0000-00

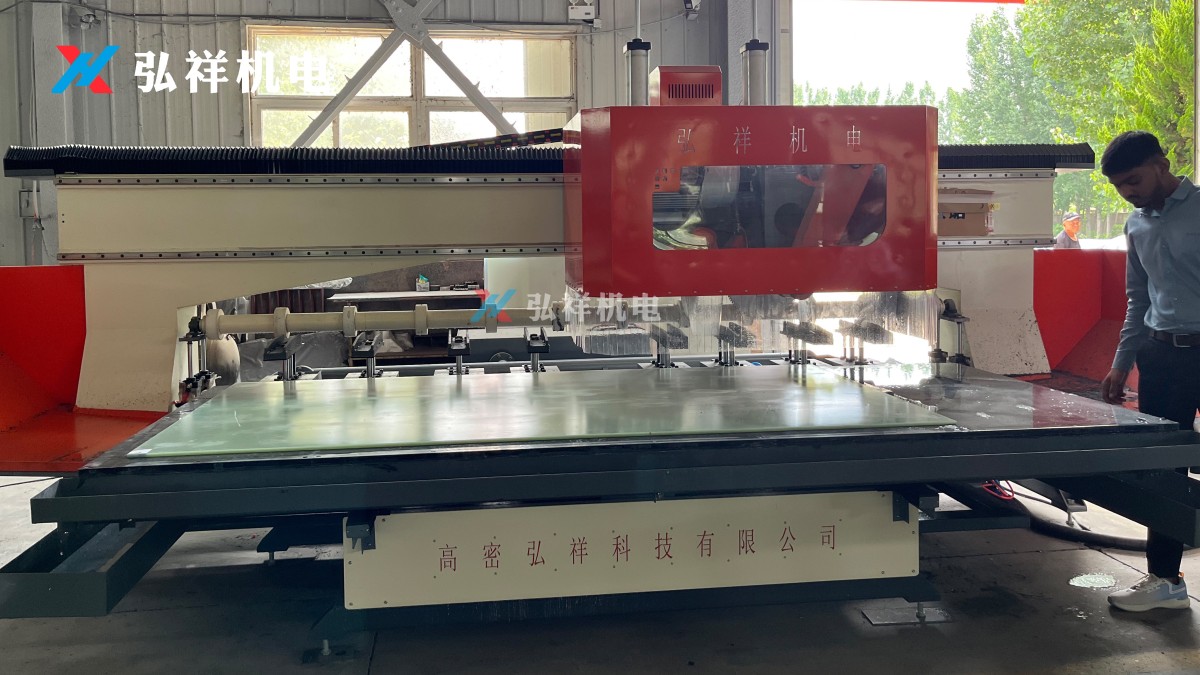

Looking for reliable transformer insulation parts processing equipment? Our bulk order guide reveals how to source high-quality CNC machines for EVA molding, laminated wood, and electrical insulation applications. As a leading Chinese manufacturer, Gaomi Hongxiang offers customized OEM solutions with competitive pricing for global buyers - from procurement teams to project managers. Discover cost-effective solutions for your transformer component production needs.

Understanding Transformer Insulation Parts Processing Equipment

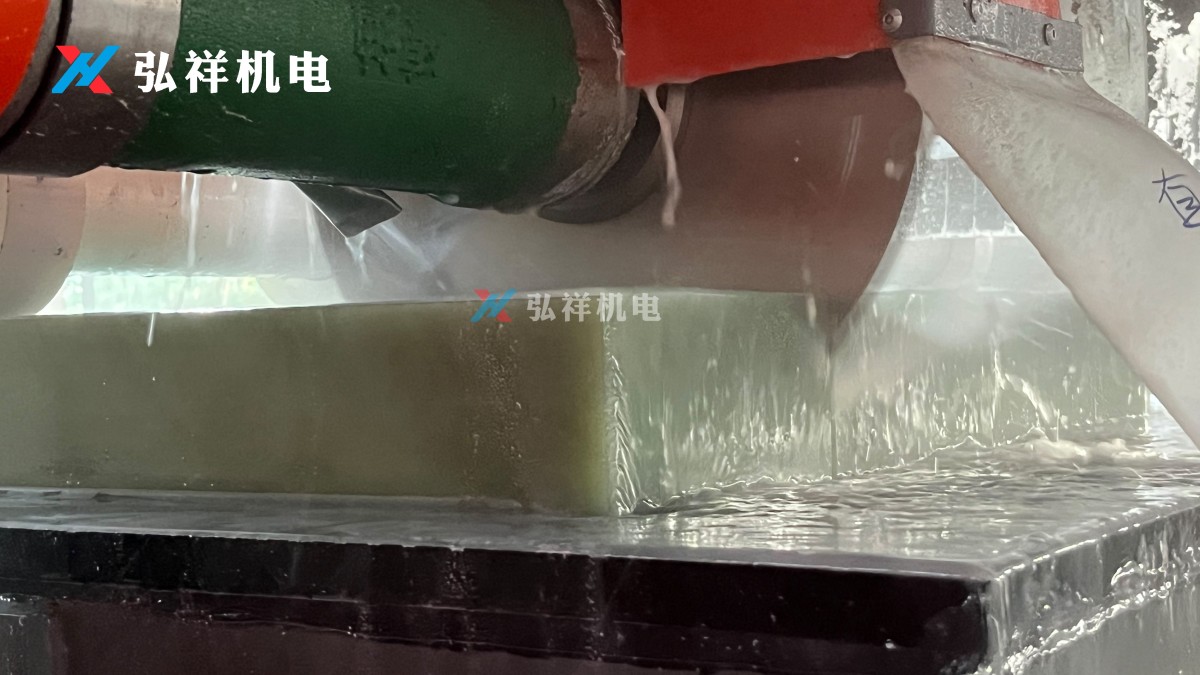

Transformer insulation parts processing equipment plays a critical role in manufacturing high-performance electrical components. These specialized CNC machines are designed to handle materials like electrical insulating cardboard, laminated wood, and EVA (ethylene-vinyl acetate) with precision. The equipment ensures dimensional accuracy and surface finish quality, which are vital for transformer insulation performance. When sourcing these machines in bulk, buyers must consider factors such as production capacity, material compatibility, and automation levels. Gaomi Hongxiang's expertise in manufacturing transformer insulation parts processing equipment for global markets ensures that each machine meets international standards for electrical insulation applications.

Key Considerations for Bulk Orders

When placing bulk orders for transformer insulation parts processing equipment, several factors can significantly impact your total cost of ownership and production efficiency. First, evaluate the machine's compatibility with your specific materials - whether you need equipment optimized for EVA molding processing, laminated wood cutting, or electrical insulation board fabrication. Second, consider the production volume requirements and whether the equipment can be scaled to meet future demand. Third, assess the level of customization needed, as OEM service options can provide tailored solutions for unique manufacturing challenges. Gaomi Hongxiang's CNC transformer insulation parts processing equipment offers flexible configurations that can be adapted to various production scenarios while maintaining consistent quality across large orders.

Material-Specific Processing Capabilities

Different transformer insulation materials require specialized processing approaches. For electrical insulation applications, the equipment must maintain tight tolerances to prevent dielectric breakdown. Laminated wood processing demands precise cutting tools that can handle the material's density without delamination. EVA molding processing equipment requires temperature-controlled components to ensure proper material flow and curing. When sourcing transformer insulation parts processing equipment in bulk, verify that the manufacturer has experience with your specific material requirements. Gaomi Hongxiang's product line includes dedicated solutions for each material type, ensuring optimal processing parameters for every application.

Cost-Saving Strategies for Bulk Purchases

Bulk ordering transformer insulation parts processing equipment presents significant opportunities for cost reduction, but requires strategic planning. Consider these approaches: First, consolidate your equipment specifications to maximize quantity discounts while meeting all operational needs. Second, explore package deals that include installation, training, and extended warranty coverage. Third, time your purchase to coincide with manufacturer production cycles for better pricing. As a leading transformer insulation parts processing equipment manufacturer in China, Gaomi Hongxiang offers volume-based pricing tiers that can reduce per-unit costs by 15-30% for large orders, while maintaining the same high standards of quality and performance.

Customization vs. Standard Models

The decision between custom transformer insulation parts processing equipment and standard models significantly impacts both cost and functionality. While custom OEM service options provide perfect solutions for unique production requirements, they typically involve higher initial costs and longer lead times. Standard CNC transformer insulation parts processing equipment offers faster delivery and lower costs, especially for bulk orders. Gaomi Hongxiang's engineering team can help evaluate your specific needs to determine the optimal balance between customization and standardization, often suggesting modular designs that combine the benefits of both approaches for electrical insulation component manufacturing.

Quality Assurance in Bulk Purchasing

Maintaining consistent quality across large orders of transformer insulation parts processing equipment requires rigorous quality control measures. Key aspects to verify include: machine-to-machine consistency in processing accuracy, durability of components under continuous operation, and compliance with international electrical insulation standards. Gaomi Hongxiang implements a comprehensive quality management system that includes pre-shipment testing of every unit, material traceability, and performance validation for EVA molding processing, laminated wood cutting, and electrical insulation applications. This ensures that bulk orders maintain the same reliability and precision as individual purchases.

Logistics and After-Sales Support

Bulk orders of transformer insulation parts processing equipment present unique logistics challenges that require careful planning. Factors to consider include: shipping method optimization to balance cost and delivery time, customs clearance procedures for international shipments, and on-site installation coordination. Equally important is evaluating the manufacturer's after-sales support capabilities, including spare parts availability, technical assistance, and maintenance services. Gaomi Hongxiang's global service network ensures prompt support for bulk equipment purchasers, with regional warehouses stocking critical components for CNC transformer insulation parts processing equipment and trained technicians available for installation and troubleshooting.

Financing and Payment Options

Large-scale purchases of transformer insulation parts processing equipment often require flexible financing solutions. Many manufacturers offer tailored payment plans for bulk orders, including phased payments tied to production milestones, leasing options, or extended credit terms. Gaomi Hongxiang works with financial partners to provide competitive financing solutions for qualified buyers, making it easier to acquire high-quality CNC equipment for EVA molding, laminated wood processing, and electrical insulation applications without straining capital resources. These options can be particularly valuable for manufacturers expanding their production capacity or upgrading existing facilities.

Why Choose Gaomi Hongxiang for Your Bulk Order

Gaomi Hongxiang Electromechanical Technology Co., Ltd. stands out as a premier source for transformer insulation parts processing equipment due to our comprehensive capabilities and global experience. Our advantages include: vertically integrated manufacturing that ensures quality control from raw materials to finished machines, extensive R&D investment in CNC technology for electrical insulation applications, and a proven track record serving markets from Southeast Asia to South America. As a full-service provider offering design, production, installation, and after-sales support, we simplify the bulk purchasing process while delivering equipment that meets the most demanding transformer component production requirements.

Ready to optimize your transformer insulation parts production with high-quality processing equipment? Contact Gaomi Hongxiang today to discuss your bulk order requirements and discover how our customized solutions can enhance your manufacturing efficiency while reducing costs. Our team of experts is ready to provide detailed specifications, pricing information, and production timelines tailored to your specific needs.

НАВИГАЦИЯ

СООБЩЕНИЕ

Запросить предложение?